What Equipment Is Similar to Rotary Dryer Components?

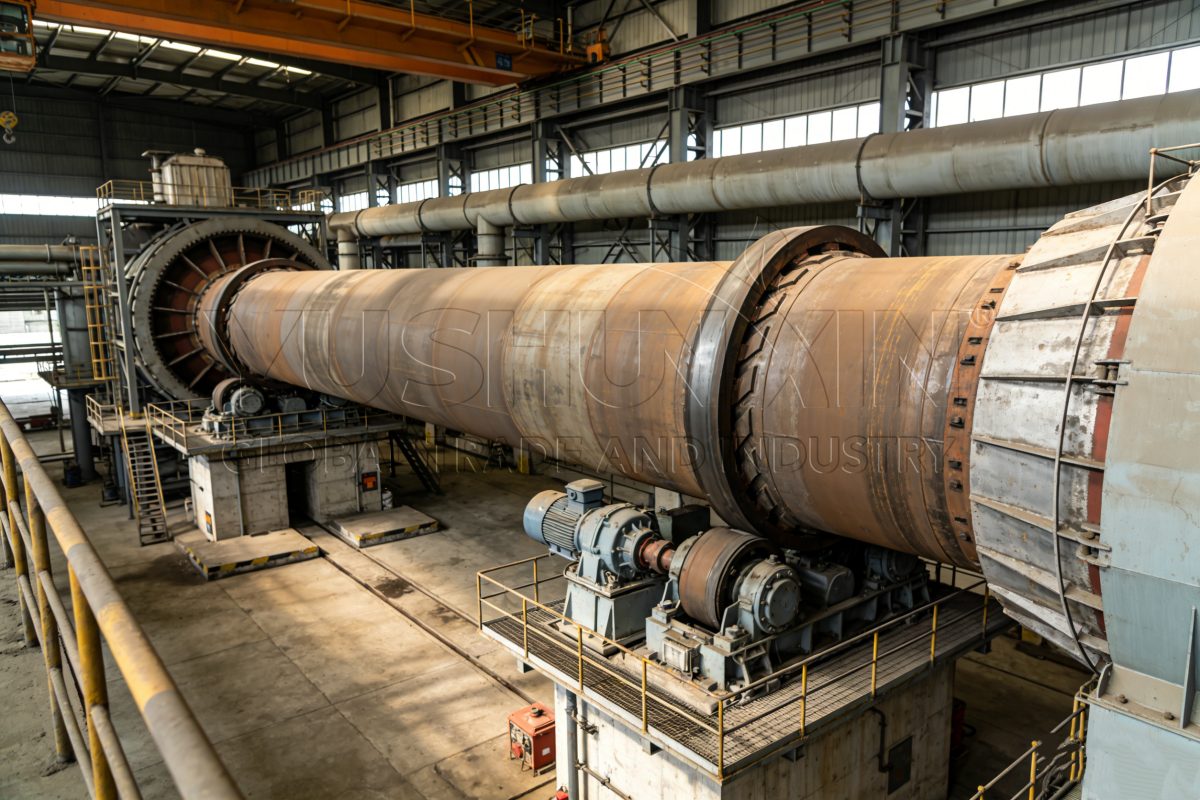

яn fact, drum dryer share the same rotating drum structure and driving system design with many rotary-type machines. Поэтому, spare parts production shows strong similarity across these rotary machines. For example, drum granulator and the new type organic fertilizer granulator with wet granulation technology use the same structure. Their cylinders, driving units, and support system use nearly identical mechanical parts, although internal functional components differ. Кроме, rotary coolers и coating machine apply the same rotating drum structure and many similar spare parts. Более того, in terms of appearance, rotary dryers and rotary kilns belong to the same rotating equipment family. Однако, rotary kilns focus on calcination processes instead of drying production. Nevertheless, they both feature slightly inclined cylindrical shells, comparable drive assemblies, and exhaust systems. So we also have the capability to design and process the corresponding accessories.

How to Customizable Design Spare Parts for Rotary Drying Machine?

Аlthough standard models of drum drying machines are available on the market, in actual industrial production, every client faces unique drying conditions like material properties, moisture content, corrosiveness, abrasiveness, and temperature. Таким образом, customizable spare parts design becomes essential for stable rotary drying processes.

1

Material Selection & Structural Optimization

Different drying materials require different structural solutions. Например, mineral slag shows high abrasion behavior during continuous drying production; Sludge show strong viscosity during moisture reduction procedures; Meanwhile, fertilizer shows corrosion behavior during long-term drying processing. Поэтому, our engineers design drum shells and main components with carbon steel, нержавеющая сталь, или alloy steel. Потому что, carbon steel offers cost efficiency, stainless steel resists acid and moisture, and alloy steel endures high temperature and friction. Also, our design team adjusts drum thickness and insulation structures for specific drying technology systems for higher thermal efficiency and lower energy consumption.

2

Two Purchase Options for Drum Dryer Spare Parts

Usually, individual rotary dryer components cost about 100–500 США доллары per unit. Однако, the purchase price for complete sets of dryer assemblies more affordable. Поэтому, our company offers two professional spare parts design and buying suggestions.

Во-первых, one model combines rotary dryer machines with full spare parts packages. When you buy our fertilizer dryers, you can select driving systems, burners, and drum components at once according to your moisture reduction requirements. Таким образом, our customer can maintain long-term stable fertilizer drying production without component replacement risks. And it ensure overall compatibility and operational efficiency of the drying system.

Во-вторых, another option focuses on OEM/ODM spare parts manufacturing for existing drying machines. Many factories already have their own drying machines. So we can redesign parts following your drawings or samples. Or we remanufacture the drying parts structure based on raw material parameters.

Drum Shell Design for Rotary Drying & Heat Preservation Systems

Тhe drum shell serves as the main body of the rotary drying machine. The shell material selection directly influences drying efficiency and thermal stability. We design drum shells with adjustable thickness, multiple materials, and optional liners based on raw materials’ characteristics.

Also, the shell material options include carbon steel, нержавеющая сталь, и composite alloy steel. For example, carbon steel shells support general fertilizer drying production with cost efficiency. Stainless steel shells support acidic fertilizer drying with corrosion resistance. Более того, composite alloy steel shells support high-temperature drying processes. Among these, a stainless drum usually costs twice as much as carbon steel for highly corrosive materials and special chemical fertilizer raw materials.

Кроме того, the thickness of the drum cylinder is highly correlated with thermal insulation performance. When your drying system requires high thermal stability, we recommend these 3 ways: 1) increasing the plate thickness of the cylinder; 2) adding external insulation layerс; 3) installing composite refractory linings. Таким образом, these design improvements reduce fuel loss and increase thermal efficiency across the entire drying system.

Combustion System Components for Rotary Drying Technology

Combustion Chamber Design for Drying Airflow Control

The combustion chamber supports the actual burning procedure and controls airflow direction during drying production. The key to designing a combustion chamber is to prevent direct contact between flames and materials, ensuring uniform drying. So, there are usually the following customization plans: 1) designing single or double shell structures; 2) adopting refractory lining; 3) adjusting chamber inclination to optimize hot air flow.

Burner Design for Energy Output & Drying Efficiency

The burner functions as the heat source of the drying system, which determines the drying efficiency and energy consumption. Таким образом, we offer many options for customizing burners with various fuels, включая electric heating, natural gas, diesel, and more. Also, our engineers will recommend the most suitable burner model and heat output scheme based on the stability of local energy supply, actual fuel price, and operating conditions. Таким образом, burning systems in your factories achieve economic operation and stable drying efficiency.

Driving System Core Parts for Continuous Drying Process

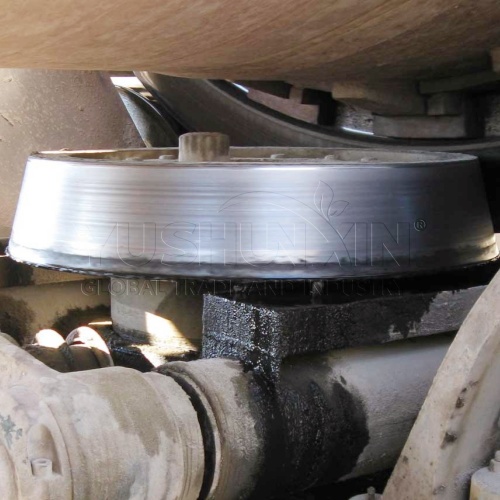

яndeed, роторные сушилки, drum granulators, coating machines, and organic granulators share the same rotating mechanical system. The drive system ensures the continuous rotation of the drying drum. So the drive system, support system, and transmission unit are highly interchangeable. What’s more, our factory manufactures these components using heavy-duty lathes, CNC centers, and gear machining equipment. The core components are as following:

Lifting Blades System Design

The lifting blade system directly controls drying efficiency. It lifts and disperses materials inside the drum, increasing contact between hot air and the product. The blade system directly influences drying time, moisture reduction efficiency, and production quality. Поэтому, our engineers customize lifting blades’ angles and patterns according to your material’s types, moisture and distribution.

Например, we recommend using arc-shaped plates for granular fertilizers, dense distribution type blades for mineral powders, и anti-adhesion spiral lifters for sticky sludge. Meanwhile, we apply anti-stick technologies include curved surfaces, perforated blades, and self-cleaning combinations. Более того, we fabricate blades from carbon steel, wear-resistant alloy, or stainless steel to extend service life and ensure consistent drying performance.

Knocking System Design for Anti-Sticking Drying Operation

The knocking system reduces material sticking during rotary drying rotation. Because it uses steel balls or small hammers to gently strike the outer shell during drum movement without damaging internal surfaces. Then, this mechanism loosens clumps without damaging the inner liner. Also, it can be flexibly configured based on drum dimensions and material characteristics. Таким образом, this system is simple and cost-effective, making it an excellent “high-value functional accessory” for customers to purchase as an add-on.