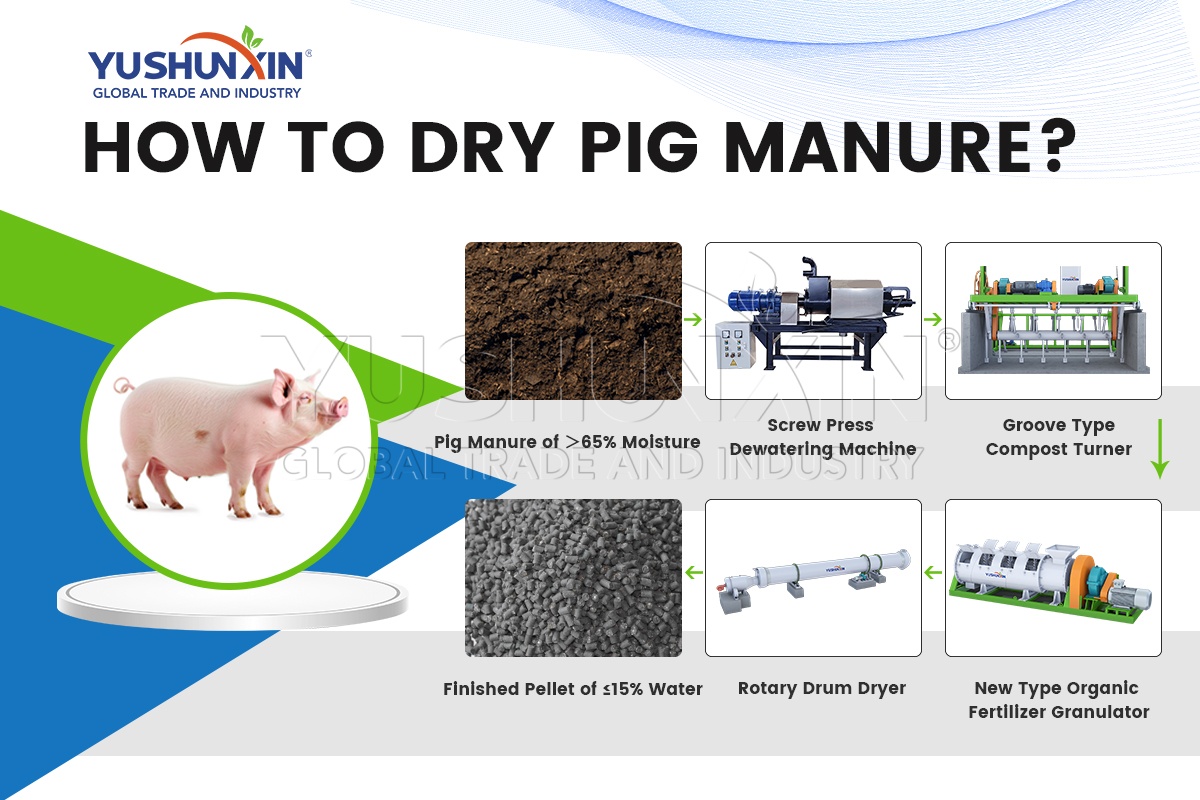

Cuáles son 4 Fases para reducir el contenido de humedad del estiércol de cerdo?

Cómo deshidratar el estiércol de cerdo para 60-65% Para el pretratamiento de fertilizantes orgánicos?

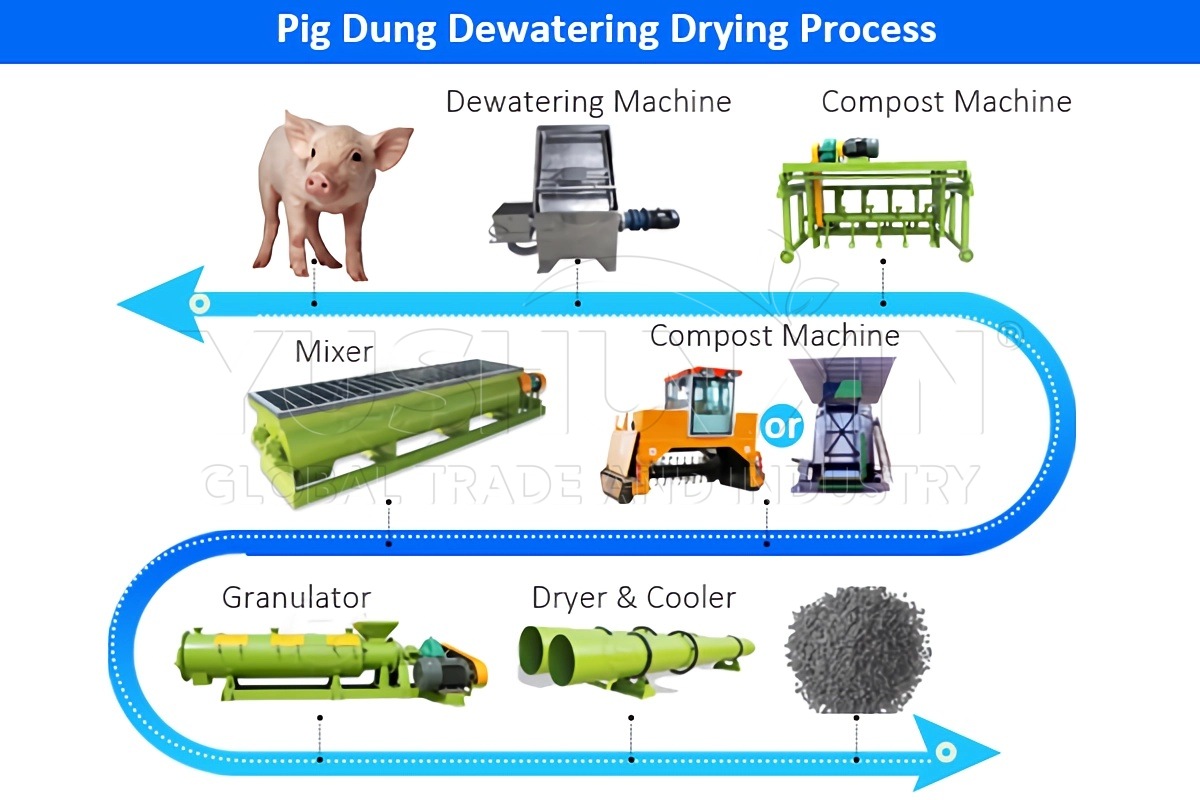

If está buscando soluciones de desagüe eficientes para procesar estiércol de cerdo, Nuestra empresa ofrece dos separadores de líquido sólido rentables. Pueden reducir el contenido de humedad de manera efectiva a 60-65% nivel. Además, Existen opciones de reducción de humedad flexibles con diversos grados de su capacidad de deshidratación. Uno es Máquina de desagüe de tornillo, con un efecto de deshidratación más fuerte, making it ideal for preparing manure for most organic applications. Another is deshidratador inclinado, Adecuado para la eliminación de heces porcinas empapadas de agua.

1

Máquina de desagüe inclinada para la deshidratación de estiércol de cerdo a 70% Contenido de agua

Honestamente, Si desea eliminar el estiércol de cerdo fresco con más contenido de agua de 85%. En este momento, Le recomendamos que compre nuestra máquina de desagüe inclinada. En efecto, La tasa de separación sólida-líquido está a la altura 80%, while you can remove part of water in pig dung. Our factory have 2 modelos de separador sólido-líquido inclinado. También, puede manejar los desechos de cerdo máximo de 40m³/h. Y los sólidos de estiércol de cerdo descargados después de la deshidratación mecánica contienen como máximo 70% humedad. Además, La malla de pantalla y la carcasa entera de la maquinaria de desagüe inclinada adoptar 304 acero inoxidable, y todos los componentes se aplican precisamente aleación de níquel. Por lo tanto, Tiene alta resistencia a la corrosión, por lo que no tiene que preocuparse por dañar esta máquina al deshidratarse.

2

Máquina de desagüe de tornillo para la deshidratación de estiércol de cerdo a 60% Contenido de agua

Si quieres procesar más el estiércol de cerdo, you may consider purchasing a spiral extrusion dewatering machine. Además, Tenemos dos modelos, Ambos que ocupan una pequeña área de 1-3 metros cuadrados. Puede deshidratar el estiércol de cerdo a 60% a la vez. Nuestro equipo puede automatizar el procesamiento del estiércol de cerdo. First, the pump sends swine manure to the feed inlet of the dehydrator. Bajo la exprimencia de las cuchillas en espiral, the wastewater flows through pipelines. And the residue after dewatering is transported to the next step by a conveyor belt. De este modo, screw extrusion dehydrator can be widely of use in the dehydration operation of high humidity residue materials before drying, Resolver con éxito el problema de la deshidratación de materiales de alta viscosidad en muchas industrias.

3 Tips for Pig Manure Moisture Removal to 30-50% During Composting Process

PAGig manure fertilizer producers usually face relatively high moisture after mechanical dewatering, typically 40–60%. Por lo tanto, you often choose composting and fermentation to convert pig dung into organic fertilizer. Entonces, you can lower the water content of pig excrement after composting to 30-50%, que es más adecuado para la granulación de fertilizantes orgánicos. Here, many livestock farms aim to design an efficient pig manure fertilizer production system. Mientras tanto, you need to consider transportation, storage, deodorization, and drying cost control. De este modo, moisture control during composting becomes a core technical process in pig dung fertilizer manufacturing.

1

Absorbent Materials & Turning Design During Pig Manure Composting Process

En efecto, adding absorbent auxiliary materials help pig feces composting reduce water content during fermentation. Por ejemplo, chips de madera, husk or straw absorb moisture and stabilize pig manure compost piles. In practical composting, a common approach is mixing “chips de madera + paja” o “rice husks + chips de madera“. Además, the ratio is based on the moisture content of the raw pig manure, with the initial moisture content ideally between 60-65% when composting with additives. También, it is important to turn pig manure regularly for aeration and microbial activities. This turning design promotes moisture evaporation and heat exchange during pig dung composting production. Consequently, this fermentation system minimizes odor and supports later granulation.

2

Secondary Fermentation Technology in Pig Manure Fermentation Pot

En efecto, adding absorbent auxiliary materials help pig feces composting reduce water content during fermentation. Por ejemplo, chips de madera, husk or straw absorb moisture and stabilize pig manure compost piles. También, it is important to turn pig manure regularly for aeration and microbial activities. This turning design promotes moisture evaporation and heat exchange during pig dung composting production. Consequently, this fermentation system minimizes odor and supports later granulation.

3

Composting Equipment Design for Pig Manure Moisture Reduction System

Processing pig manure with composting equipment is also an effective method for moisture reduction. Our company provides 3 kinds of rail type compost turners and 2 kinds of window type compost turners for pig manure composting. This composting process shortens dewatering time while ensuring uniform fermentation. Como resultado, your pig manure fertilizer production line runs efficiently and increases production capacity after moisture reaches 30-50%.

TOP 3 Pig Manure Moisture Removal Methods During Granulation Process

Actually, pig dung moisture usually reaches 20-40% after fermentation. Sin embargo, organic fertilizer producers still face moisture control pressure during pig dung pellet making procedures. Entonces, most of the cases we recommend to use our secadora de tambor giratorio para secar. After the drying, cooling or coating processes, the moisture content of the pig manure particles reaches the marketing standard, menos que 10%.

1

Mezcla de sustancias auxiliares

After dewatering and composting, if you want to further reduce the pig dung’s moisture content to below 30%, you can do the following during the mixing stage. En primer lugar, our plant recommends increasing the blending frequency and time to promote moisture evaporation. En segundo lugar, you can also blend dry powder materials to absorb excess water from pig dung compost. Por ejemplo, you can mix pig manure with nitrogen, fósforo, and potassium powders to adjust moisture and nutrient balance. Most importantly, nuestro mezclador horizontal’s rotating blades breaks up the pig manure compost pile, forming thin layers of 20-30 mm thickness for faster air contact. Our company offers multiple mixer models for different pig dung production scales. Por ejemplo, el Scab-1630 has an output of 10-15 T/H, a rotating speed of 21 r/min, and a power of 22 kW.

2

Proceso de granulación

During granulation, it’s necessary to pay attention to the moisture control. Too much water causes soft pellets and uneven granule strength, while less water is hard for pellet forming. Our company supplies four types organic fertilizer granulator types for pig dung processing. Entre ellos, el Nuevo tipo de fertilizante orgánico es bien recibido por los clientes. Because this pelletizer uses high-speed mechanical stirring to make pig manure powder continuous mixing and ball making. De este modo, its granulating procedure increases pellet roundness and particle appearance. Además, we offers 5 models with capacities of 1-8 t/h for different scales of pig manure fertilizer production. Due to wet granulation technique, this stage will increase the moisture content of the pig manure pellets.

3

Drying & Post‑Treatment

After granulation, you can use our organic fertilizer dryer for precise drying and moisture reduction to meet standard requirements. This drying equipment maintains temperature and airflow balance to ensure uniform heat exchange with pig manure pellets. Mientras tanto, adjusting the rotation speed and inclination angle to form an even material curtain within the drum, improving drying uniformity. Después del secado, pig manure fertilizer granules reach a moisture content of around 10-14%. Entonces, el enfriador uses relatively dry inlet air. In some cases, partial use of drying exhaust air improves cooling air dryness and efficiency. Typically, our cooling process controls the temperature of the pig manure organic fertilizer particles to within 5 ℃ above ambient. Por lo tanto, it can prevent pig manure pellet surface condensation and secondary moisture absorption. Además, you can choose a coating tank for uniform spraying hydrophobic oil or wax coatings. Or you can select the coating drum machine thoroughly to mix moisture-resistant materials, such as talc or bentonite. Finalmente, this coating process reduces pig dung pellet moisture absorption, dusting, and caking during storage. And adding the amount of coating materials on the order of 0.2-1.0% of the organic fertilizer particle mass is enough.