영형n January 2nd, 2024, Shunxin 기계 received an industrial dryer inquiry from Lithuania. And this customer expressed interest in our drying machine. 게다가, the client sought drying solution regarding the feasibility of our 로타리 드럼 건조기 for drying Fe2영형3 and silica sand. 따라서, the following is the subsequent communication process, including equipment information, and the recommended proposal we provided to meet the Lithuanian client’s specific needs.

What Are Drying Requirements of Lathuanian Customer?

Our team has held in-depth conversations with Lithuanian clients via effective communication channels. 그 다음에, we identified their specific needs, including the desired drying capacity, moisture reduction targets, and existing infrastructure considerations. 또한, we know they’re making industrial materials and want to dry 2 tons of Fe2영형3 and silica sand per hour. 게다가, they hope to control the moisture content below 5%, with a budget of approximately $10,000.

What 디rying 에스olutions 디o we 영형ffer for Drying Fe2영형3 & 에스ilica 에스그리고 in Lithuania?

Our expert engineers acted fast after doing an examination of customer demands. 따라서, we recommended this small model of rotary drum dryer – SXHG-1010, which can dry 2-4 톤 of Fe2영형3 and silica sand per hour. 그 동안에, the price is about $6,000. 게다가, it can fully meet their drying needs, ensuring that the water content after drying is below 5%. And we promise to customize solutions with a focus on optimizing heat source selection, improving heat transfer efficiency, and adopting advanced control technology. 결과적으로, these enhancements seek to maximize performance in the drying of Fe2영형3 and silica sand while reducing energy usage and preserving product quality.

What Equipment in 영형ur 나ndustrial 디rying 에스olutions for Lithuanian Customer?

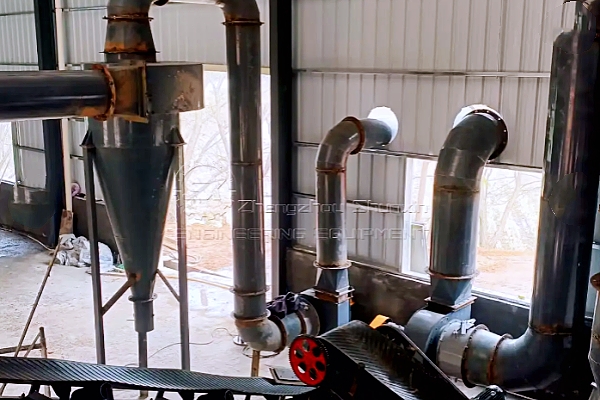

After communicating with the customer, we cancelled the rotary cooler and made the budget meet their needs. Following careful analysis and extensive consultation, we offer an upgraded supporting facility, 6C induced draft fan, which has a big air volume and a solid frame made of 탄소강.

에이dditionally, our Lithuanian customer are concerned that the hardness of Fe2영형3 and silica sand may damage the dryer. We inform customer not to worry about this. Because we will cover the inner wall of the drum with anti-corrosion and wear-resistant coatings to provide maximum normal operating duration and service life while minimizing maintenance downtime and expenses.

에프inally, Lithuanian customer have inquired about measures to reduce energy costs, as their coal and natural gas rely on imports. Because diesel costs are cheap, we have customized diesel combustion engine 그리고 뜨거운 폭발로 for them. In summary, they can effectively remove moisture and produce consistent and high-quality drying products by applying our equipment.

What 에이fter-sales 에스ervice 디o we 영형ffer for Lithuanian 기음ustomer?

In Shunxin, our commitment to our clients extends beyond just delivering appropriate drying solutions. 우선, we provide comprehensive training and technical support to our customer to ensure a smooth transition and effective operation of rotary drum dryer. 또한, we offer a responsive 7*24시간 after-sales service, addressing any inquiries promptly and providing necessary spare parts when needed. 게다가, we inform our Lithuanian customer that it is in stock. And we can send out the dryer in 7-15 날 with a one-year warranty.

결론적으로, we successfully closed the deal with our client from Lithuania. In addition to drying iron oxide and silica sand, our drying machine is capable of handling various other products such as agricultural crops, 바이오 매스, and minerals. Should you have any further inquiries or require additional information, please do not hesitate to contact us.