Hur man avvattnar grisgödsel till 60-65% för förbehandling av organisk gödsel?

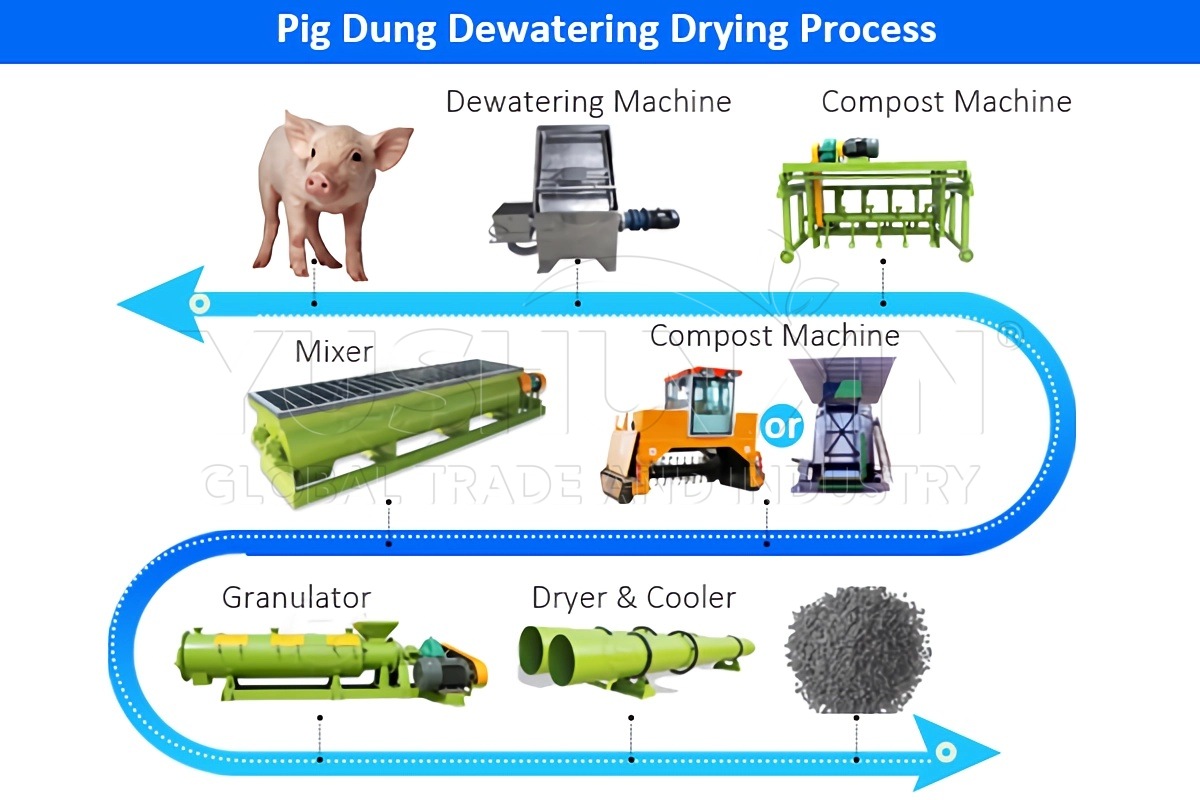

jagom du letar efter effektiva avvattningslösningar för bearbetning av grisgödsel, vårt företag erbjuder två kostnadseffektiva fast-vätskeseparatorer. De kan minska fukthalten effektivt ner till 60-65% nivå. Dessutom, det finns flexibla fuktreducerande alternativ med varierande grad av deras uttorkningsförmåga. En är skruvpress avvattningsmaskin, med starkare uttorkningseffekt, making it ideal for preparing manure for most organic applications. Another is lutande dehydrator, lämplig för bortskaffande av vattendränkt svinavföring.

1

Lutande avvattningsmaskin för Grisgödseluttorkning till 70% Vatteninnehåll

Ärligt, om du vill slänga färsk grisdynga med mer vattenhalt av 85%. Vid den här tiden, vi råder dig att köpa vår lutande avvattningsmaskin. Verkligen, fast-vätskeseparationshastigheten är upp till 80%, while you can remove part of water in pig dung. Our factory have 2 modeller av lutande fast-vätskeseparator. Också, den klarar grisavfall max 40m³/h. Och den utsläppta grisgödselns fasta partiklar efter mekanisk uttorkning innehåller som mest 70% fukt. Dessutom, skärmnätet och hela skalet på lutande avvattningsmaskineri antar 304 rostfritt stål, och alla komponenterna tillämpar exakt nickellegering. Därför, den har hög korrosionsbeständighet så du behöver inte oroa dig för att skada den här maskinen genom att torka grisgödsel med hög luftfuktighet.

2

Skruvpress avvattningsmaskin för Grisgödseluttorkning till 60% Vatteninnehåll

Om du vill vidareförädla grisgödsel, you may consider purchasing a spiral extrusion dewatering machine. Dessutom, vi har två modeller, som båda upptar en liten yta av 1-3 kvadratmeter. Det kan torka ut grisdynga ner till 60% i sänder. Vår utrustning kan automatisera bearbetningen av grisgödsel. First, the pump sends swine manure to the feed inlet of the dehydrator. Under klämningen av spiralblad, the wastewater flows through pipelines. And the residue after dewatering is transported to the next step by a conveyor belt. Således, screw extrusion dehydrator can be widely of use in the dehydration operation of high humidity residue materials before drying, framgångsrikt lösa problemet med uttorkning av högviskösa material i många industrier.

3 Tips for Pig Manure Moisture Removal to 30-50% During Composting Process

Pig manure fertilizer producers usually face relatively high moisture after mechanical dewatering, typically 40–60%. Därför, you often choose composting and fermentation to convert pig dung into organic fertilizer. Sedan, you can lower the water content of pig excrement after composting to 30-50%, som är mer lämpad för organisk gödselgranulering. Here, many livestock farms aim to design an efficient pig manure fertilizer production system. Under tiden, you need to consider transportation, storage, deodorization, and drying cost control. Således, moisture control during composting becomes a core technical process in pig dung fertilizer manufacturing.

1

Absorbent Materials & Turning Design During Pig Manure Composting Process

Verkligen, adding absorbent auxiliary materials help pig feces composting reduce water content during fermentation. Till exempel, flis, husk or straw absorb moisture and stabilize pig manure compost piles. In practical composting, a common approach is mixing “flis + halm” or “rice husks + flis“. Dessutom, the ratio is based on the moisture content of the raw pig manure, with the initial moisture content ideally between 60-65% when composting with additives. Också, it is important to turn pig manure regularly for aeration and microbial activities. This turning design promotes moisture evaporation and heat exchange during pig dung composting production. Consequently, this fermentation system minimizes odor and supports later granulation.

2

Secondary Fermentation Technology in Pig Manure Fermentation Pot

Verkligen, adding absorbent auxiliary materials help pig feces composting reduce water content during fermentation. Till exempel, flis, husk or straw absorb moisture and stabilize pig manure compost piles. Också, it is important to turn pig manure regularly for aeration and microbial activities. This turning design promotes moisture evaporation and heat exchange during pig dung composting production. Consequently, this fermentation system minimizes odor and supports later granulation.

3

Composting Equipment Design for Pig Manure Moisture Reduction System

Processing pig manure with composting equipment is also an effective method for moisture reduction. Our company provides 3 kinds of rail type compost turners and 2 kinds of window type compost turners for pig manure composting. This composting process shortens dewatering time while ensuring uniform fermentation. Som ett resultat, your pig manure fertilizer production line runs efficiently and increases production capacity after moisture reaches 30-50%.

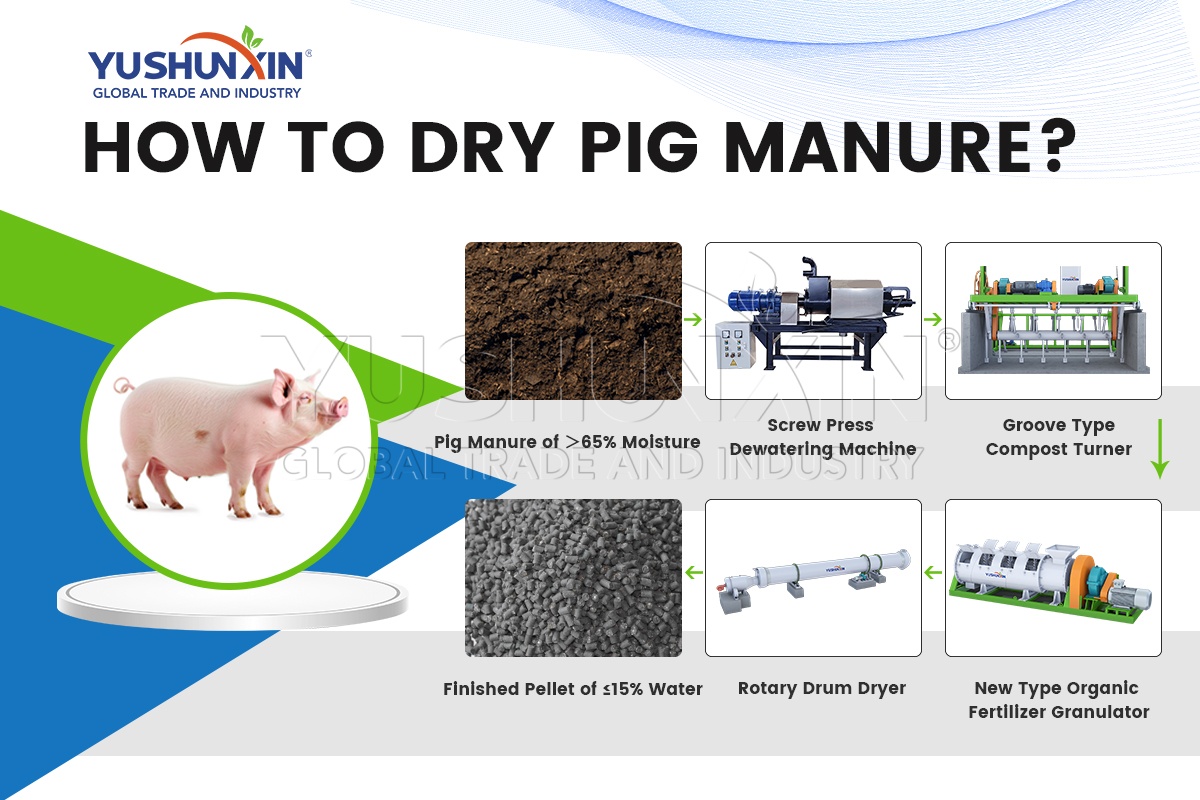

TOP 3 Pig Manure Moisture Removal Methods During Granulation Process

Actually, pig dung moisture usually reaches 20-40% after fermentation. Ändå, organic fertilizer producers still face moisture control pressure during pig dung pellet making procedures. So, most of the cases we recommend to use our roterande trumtork för torkning. After the drying, cooling or coating processes, the moisture content of the pig manure particles reaches the marketing standard, mindre än 10%.

1

Blandning av hjälpämnen

After dewatering and composting, if you want to further reduce the pig dung’s moisture content to below 30%, you can do the following during the mixing stage. För det första, our plant recommends increasing the blending frequency and time to promote moisture evaporation. För det andra, you can also blend dry powder materials to absorb excess water from pig dung compost. Till exempel, you can mix pig manure with nitrogen, phosphorus, and potassium powders to adjust moisture and nutrient balance. Most importantly, our horisontell blandare’s rotating blades breaks up the pig manure compost pile, forming thin layers of 20-30 mm thickness for faster air contact. Our company offers multiple mixer models for different pig dung production scales. For instance, de SXWJ-1630 has an output of 10-15 t/h, a rotating speed of 21 r/min, and a power of 22 kW.

2

Granuleringsprocess

During granulation, it’s necessary to pay attention to the moisture control. Too much water causes soft pellets and uneven granule strength, while less water is hard for pellet forming. Our company supplies four types organic fertilizer granulator types for pig dung processing. Bland dem, de ny typ organisk gödselgranulator tas väl emot av kunderna. Because this pelletizer uses high-speed mechanical stirring to make pig manure powder continuous mixing and ball making. Således, its granulating procedure increases pellet roundness and particle appearance. Dessutom, we offers 5 models with capacities of 1-8 t/h for different scales of pig manure fertilizer production. Due to wet granulation technique, this stage will increase the moisture content of the pig manure pellets.

3

Drying & Post‑Treatment

After granulation, you can use our organic fertilizer dryer for precise drying and moisture reduction to meet standard requirements. This drying equipment maintains temperature and airflow balance to ensure uniform heat exchange with pig manure pellets. Under tiden, adjusting the rotation speed and inclination angle to form an even material curtain within the drum, improving drying uniformity. After drying, pig manure fertilizer granules reach a moisture content of around 10-14%. Sedan, de cooler uses relatively dry inlet air. In some cases, partial use of drying exhaust air improves cooling air dryness and efficiency. Typically, our cooling process controls the temperature of the pig manure organic fertilizer particles to within 5 ℃ above ambient. Därför, it can prevent pig manure pellet surface condensation and secondary moisture absorption. Dessutom, you can choose a coating tank for uniform spraying hydrophobic oil or wax coatings. Or you can select the coating drum machine thoroughly to mix moisture-resistant materials, such as talc or bentonite. Slutligen, this coating process reduces pig dung pellet moisture absorption, dusting, and caking during storage. And adding the amount of coating materials on the order of 0.2-1.0% of the organic fertilizer particle mass is enough.