On July 5th, 2024, Yushunxin, a professional manufacturer of fertilizer equipment, received an inquiry from a small farm owner in Colombia. This farmer operates a 200-cattle farm and faces the daily challenge of managing approximately 5 tons of cow manure. With a limited budget, he was seeking a simple and efficient solution to convert this manure into fertilizer for his farm. His initial inquiry was about a solid-liquid separator, which he believed would be a good starting point for his manure management needs.

What Are Fertilizer Manufacturing Requirements of the Colombian Customer?

The Colombian farmer’s primary requirement was straightforward: he needed a cost-effective and efficient solution for processing cow manure into usable fertilizer. Given the farm’s modest scale, he was particularly interested in equipment that could handle the daily waste output without excessive investment. His goal was to turn the cow manure into a valuable resource, improving the soil quality on his farm and reducing waste.

However, his initial budget constraints posed a challenge. He was looking for a solution that would not only be affordable but also simple to operate, given the limited technical resources available on his farm. The equipment needed to be reliable, low-maintenance, and capable of processing the manure into a form that could be directly applied as fertilizer.

What Dewatering Plan We Offer is Suitable for the Colombian Customer?

Understanding the customer’s needs and constraints, Yushunxin initially recommended a screw press dewatering machine. This solid-liquid separator, priced at $1,500, could process between 10-15 cubic meters per hour, making it a viable option for the farmer’s daily manure output. The screw press dewatering machine is designed to efficiently separate liquid from solids, reducing the moisture content of the manure and making it easier to handle and store.

However, after discussing the machine’s processing capacity with the customer, it became clear that the efficiency of this model might not fully meet his expectations. The farmer expressed concerns that the processing speed might be too slow to keep up with the daily volume of manure, which led us to reconsider our proposal.

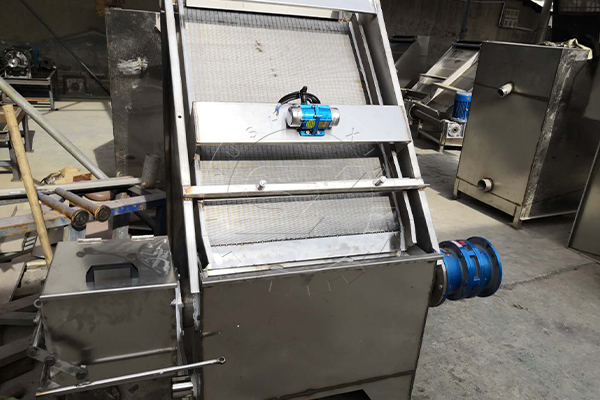

To better suit the farmer’s needs, we recommended upgrading to an inclined solid-liquid separator. This model, priced at $2,000, offered a higher processing capacity and could handle the farmer’s requirements more effectively. The slanting screen separator is capable of processing larger volumes of manure more quickly, ensuring that the farmer could manage his daily output without any backlog.

Additionally, we suggested the use of a flat die granulator, priced at a very affordable $400. This granulator could produce 2-10mm cylindrical organic fertilizer pellets from the separated manure, adding value to the waste by turning it into high-quality organic fertilizer. This secondary processing step not only makes the manure easier to apply but also improves its effectiveness as a soil amendment.

Buying the Right Equipment with Considerate Service from Yushunxin

The total transaction price for the equipment package, including the slanting screen solid-liquid separator and the flat die granulator, came to $2,400. However, to accommodate the farmer’s budget, we offered a 5% discount, bringing the final price down to $2,274.

Throughout the sales process, we maintained close communication with the customer. We provided detailed images, videos of the machines in operation, and all necessary certification documents to assure him of the quality and reliability of our products. After several discussions and clarifications, the farmer felt confident in his decision and agreed to move forward.

The customer made an initial down payment of 40% to begin production. Once the machines were ready, we sent a video of the equipment being tested to ensure it met his expectations. Satisfied with the results, the farmer paid the remaining balance on August 23rd, 2024. We then prepared the equipment for shipment to Colombia.

Yushunxin’s commitment to providing tailored solutions and exceptional customer service played a crucial role in this successful transaction. The equipment, carefully selected to meet the specific needs of the Colombian farmer, will soon be enhancing his farm’s efficiency by converting waste into valuable organic fertilizer.

Beyond solid-liquid separators and granulators, Yushunxin offers a wide range of fertilizer production equipment to meet diverse agricultural needs. Whether you are looking to process organic waste, improve soil health, or boost crop yields, our comprehensive solutions can help you achieve your goals. Contact us today to explore how we can assist you in making your farm more sustainable and productive.