Dehydrator

The majority of small farmers and fertilizer plants have been thinking about how to deal with animal manure, both to protect the environment and to create wealth. To address this issue, the small screw press dewatering equipment with a small footprint, simple operation, and straightforward installation, has become the first choice of most farms.

What Can You Know about Small Screw Press Dewatering Equipment?

In addition, this dewatering machine can do solid-liquid separation of high-concentration organic waste or wastewater, e.g. livestock and poultry dung like chicken, cow, horse, sheep, pig manure, wine lees, kitchen waste, fruits and vegetables, Chinese medicine residues, starch pulp, bagasses, paper pulp, river mud, biogas residue, etc.

What’s more, the small solid-liquid separator is mostly of use for waste with water content less than 65%, whereas manure with moisture greater than 75% require the inclined dewatering machine. Moreover, the water content of the solid materials after separation is in the range of 30-40% or less.

How Does A Small Screw Press Dewatering Machine Work?

What Is This Small Dewatering Equipment composition?

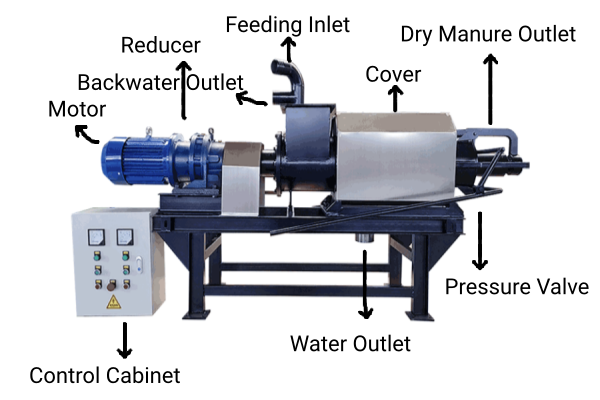

Screw press solid-liquid separator mainly consists of the main body, non-clogging pump, pipeline, electrical control cabinet and other devices. Meanwhile, the main body contains the motor, the reducer, the screen mesh, the screw press, the feeding port, the discharging port, the cleaning observation port and the water outlet.

What Is The Work Principle of Screw Press Dewatering Machine?

1 Firstly, the non-clogging pump supporting the dewatering machine elevates and sends the unfermented feces to the dewatering machine. At this time, through the electric power, the screw press pushes the manure gradually to the front of the machine. At the same time, it constantly raises the pressure of the front edge.

2 The rotating screw pushes materials forward to extrusion section. Under the compression of two forces, the pressure of the pressure spring and the thrust of the screw, this equipment extrudes materials’ moisture and then discharges by the screen mesh. In the meantime, it accelerates to drop materials under the action of the motor.

3 The work of the screw press is continuous. When the material is generally pumped into the body, the pressure of the front edge is increasing. Besides, when it reaches a certain degree, the discharge port will be opened and extruded materials out. Thus, you can achieve the purpose of solid-liquid separation.

Our Technical Parameters

|

Model |

Capacity (m³/h) | Power (kw) | Dimensions (mm) |

|

SXTS-180 |

10-15 | 4 |

1850×650×1150 |

| SXTS-230 | 15-20 | 5.5 |

1850×800×1150 |

Note: In order to control the speed and moisture content of the discharging, you can adjust the clump weighting under the main body to achieve a satisfactory and appropriate state of the discharging.

Why to Choose Our Small Screw Press Dewatering Machine?

1. Our small dewatering equipment is affordable.

Our company, shunxin, is a professional manufacturer for organic fertilizer production equipment, with more than 20 years of research and development experience.

- Firstly, the single dewatering machine by our design is small in size and occupies an area of 1.5-3m³, which can save a lot of land construction.

- Secondly, there is no need for the flocculant agent to reduce costs. You can also agglomerate the suspended particles by the screw press.

- Besides, our dewatering machine has a high degree of automation, low energy consumption and lower price. Also, it is easy to install and maintain with low maintenance costs.

2. Our plant adhere to the principle of human design.

- Firstly, we will ask your opinion in advance on the design details of electric control cabinet, the observation port, the connector of inlet port and outlet port, so that you can carry out safe and convenient operation.

- Secondly, we reserve the cleaning port of screen mesh, which can realize the direct cleaning without dismantling this machine. Furthermore, it is so easy to operate that you just press the start and stop button to control.

- According to customers’ budget, we suggest two feeding ways — by the submerged pump or by the hopper. Also, you are optional for the installation of movable wheels under the dewatering machine, so it is easy to change the working position.

3. Our dewatering equipment is solid and durable.

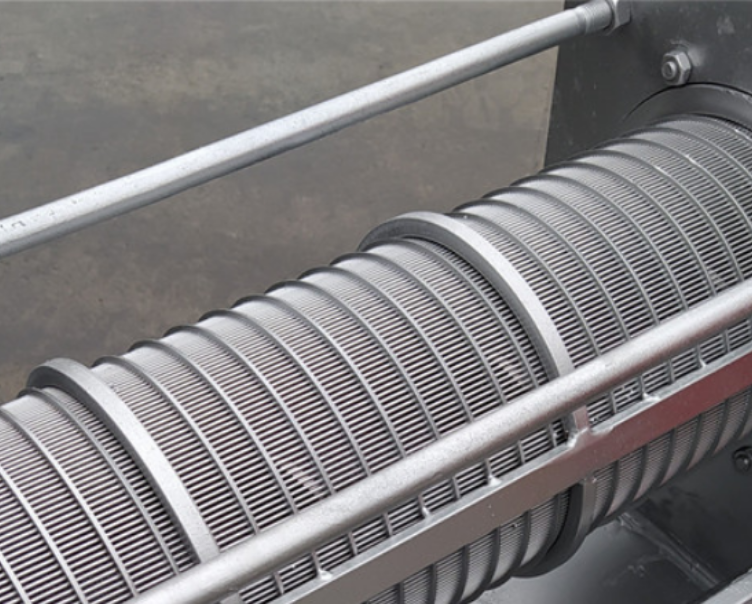

- Firstly, we produce the shell, the screen mesh, the screw press and spiral blades of this series of dewatering machine with high-quality 304 stainless steel and alloy through special process.

- Secondly, our plant spray wear-resistant layer on the key parts of the screw press, and weld a layer of alloy cutter head on the surface of the spiral blades. Therefore, it can increase the wear resistance and greatly extends the service life of the dewatering equipment.

Another Small Dewatering MachineRotary Drum Solid-liquid Separator

After years of research, our company has developed another dehydrator, which improves properly the details of the original dewatering machine. Thus, rotary drum solid-liquid separator is improved based on the shortcomings of traditional dewatering machines. Moreover, it is suitable for disposing low-concentration, low solid content and slight materials. Besides, it enhances the treatment efficiency and solves the problems of high solid content in drainage.

When Can You Use Drum Small Dewatering Machine?

For one thing, drum dewatering machine can deal with raw materials with high moisture, such as manure by rinsing or water submerging, duck manure, biogas residue and biogas slurry.

- Because the particles in water-soaked feces are tiny and contain a lot of water. Therefore, the standard solid-liquid separation system cannot filter entirely, and then solid fecal particles circulate back into the storage container (septic tank) with liquid. The solid-liquid separation machinery works ineffectively for a long time, wasting energy.

For another thing, it is capable of separating the tiny suspended substances in the liquid and organic residue to the maximum extent, like phytoplankton or zooplankton, so as to achieve the purpose of recycle of useful matter.

How Does A Small Drum Dewatering Machine Work?

This machine applies a secondary separation process.

- Firstly, you can thoroughly mix the feces in the storage tank through the mixing system to achieve the more uniform consistency.

- Then, the transfer pump sends materials to the drum. Through the filtration screen, the sewage enters into a reservoir or sewage treatment system.

- And, the solid substances enters the screw press by the spiral device. This way can reduce material moisture at a certain degree.

Drum dewatering machine adopts the unique split design — the fecal filtration and solid-liquid separation operate independently. Meanwhile, you can adjust according to the actural situation. And there are few operational faults, simple maintenance and easy operation.

What Are The Features of Rotary Drum Dewatering Machine?

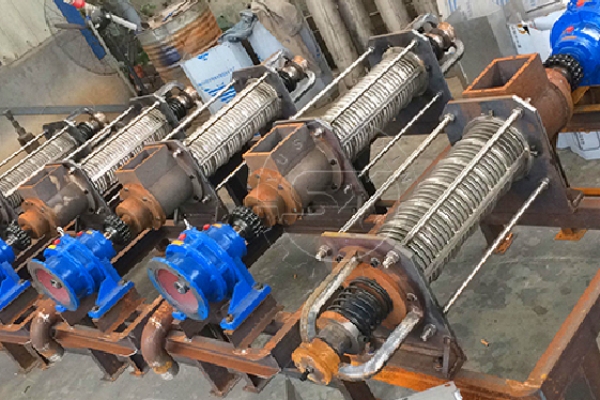

We can customize the dewatering machine models with a daily capacity ranging from 10 to over 200 tons. Simultaneously, our business includes customization of the rotary drum dryer with a screw press dewatering machine, which can dry materials to a moisture content of about 15%. When you buy our soli-liquid seperator, we give you all the parts and the high-quality pump. Thus you only need to prepare the power supply to use it.

Honestly, we process the full set of equipment for organic fertilizer production, from free installation to technical debugging. We ensure that the dewatering drying equipment manufacturing line is put into production on schedule. Also, the date of delivery is determined by client demand and manufacturing arrangements.